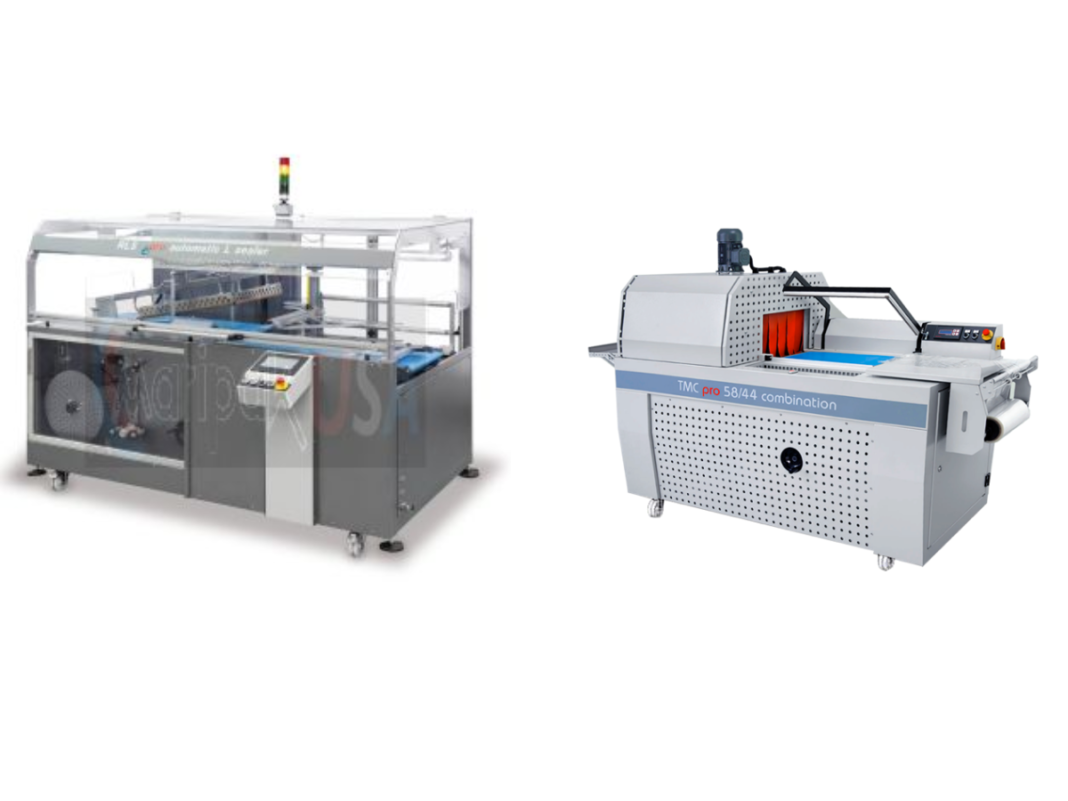

Packaging is crucial for product presentation and preservation. In today’s fast-paced manufacturing environments, maintaining high packaging quality and consistency standards is essential. One technology that significantly enhances packaging processes is the automatic side-sealing machine. This equipment, when integrated with complementary tools like a shrink tunnel machine, can greatly influence the effectiveness of your packaging operations.

Understanding Automatic Side Sealing Machines

An automatic side sealing machine is designed to seal the sides of packages automatically, ensuring that products are securely enclosed for distribution. This machine operates with high precision, offering benefits beyond mere efficiency. By automating the sealing process, manufacturers can achieve consistent and reliable sealing, which is crucial for maintaining the integrity of the packaged products.

Key Features and Benefits

- Consistency and Quality Control: One of the primary advantages of using an automatic side sealing machine is its ability to produce consistent results. The machine is engineered to perform repetitive tasks precisely, reducing the likelihood of human error and variability. This consistency ensures that each package is sealed to the same high standard, enhancing the overall quality of the product presentation.

- Increased Efficiency: Automating the side sealing process streamlines operations and increases throughput. Unlike manual sealing methods, which are time-consuming and labour-intensive, automatic machines can process large volumes of packages quickly and accurately. This efficiency speeds up the packaging line, reduces labour costs, and minimizes operational delays.

- Versatility: Automatic side sealing machines can handle various packaging materials, including plastics, films, and laminated materials. This adaptability makes them suitable for various products, from food to industrial goods. Handling different materials without compromising the sealing quality is a significant advantage for manufacturers.

The Role of Heat Shrink Tunnel Machines

Many packaging lines incorporate a heat shrink tunnel machine to complement the effectiveness of an automatic side sealing machine. This device applies heat to shrink the packaging film tightly around the product, providing an extra layer of protection and enhancing the overall appearance of the package.

Enhancing Packaging Integrity

The integration of a heat shrink tunnel machine with an automatic side sealing machine offers several benefits:

- Improved Protection: Heat shrink tunnels apply controlled heat to shrink the film around the package, creating a tight seal that protects the product from environmental factors such as moisture, dust, and contaminants. This added layer of protection is precious for products that require extended shelf life or to withstand rough handling during transportation.

- Professional Appearance: Shrink-wrapping also contributes to a professional and aesthetically pleasing appearance. The tight-fitting film reduces the risk of package shifting and ensures that labels and branding are prominently displayed. This professional presentation can enhance the product’s appeal and contribute to positive consumer perceptions.

- Increased Durability: Shrink-wrapped packages are less likely to suffer from damage during shipping and handling. The snug fit provided by the heat shrink tunnel helps to secure the product, reducing the risk of breakage or deformation. This durability is particularly important for fragile or high-value items.

Best Practices for Integration

To maximize the benefits of an automatic side sealing machine and a heat shrink tunnel machine, consider the following best practices:

- Regular Maintenance: Ensure that both machines are regularly maintained and calibrated to perform at their best. Regular maintenance helps prevent downtime and ensures that the machines operate optimally.

- Training and Operation: Proper operator training is essential to ensure that both machines are used effectively. Operators should be familiar with the machine settings, troubleshooting procedures, and safety protocols.

- Quality Control: Implement robust quality control measures to monitor the packaging line’s performance. Regular inspections and quality checks can help identify and address issues promptly, ensuring the packaging meets the required standards.

Conclusion

The integration of an automatic side sealing machine with a tunnel machine can significantly enhance packaging quality and consistency. Manufacturers can achieve greater efficiency, improved product protection, and a professional package appearance by automating the sealing process and incorporating shrink-wrapping technology. Embracing these technologies not only streamlines operations but also contributes to overall product excellence, meeting the demands of modern packaging standards. For more information on optimizing your packaging processes, consider contacting industry experts and exploring advanced packaging solutions.